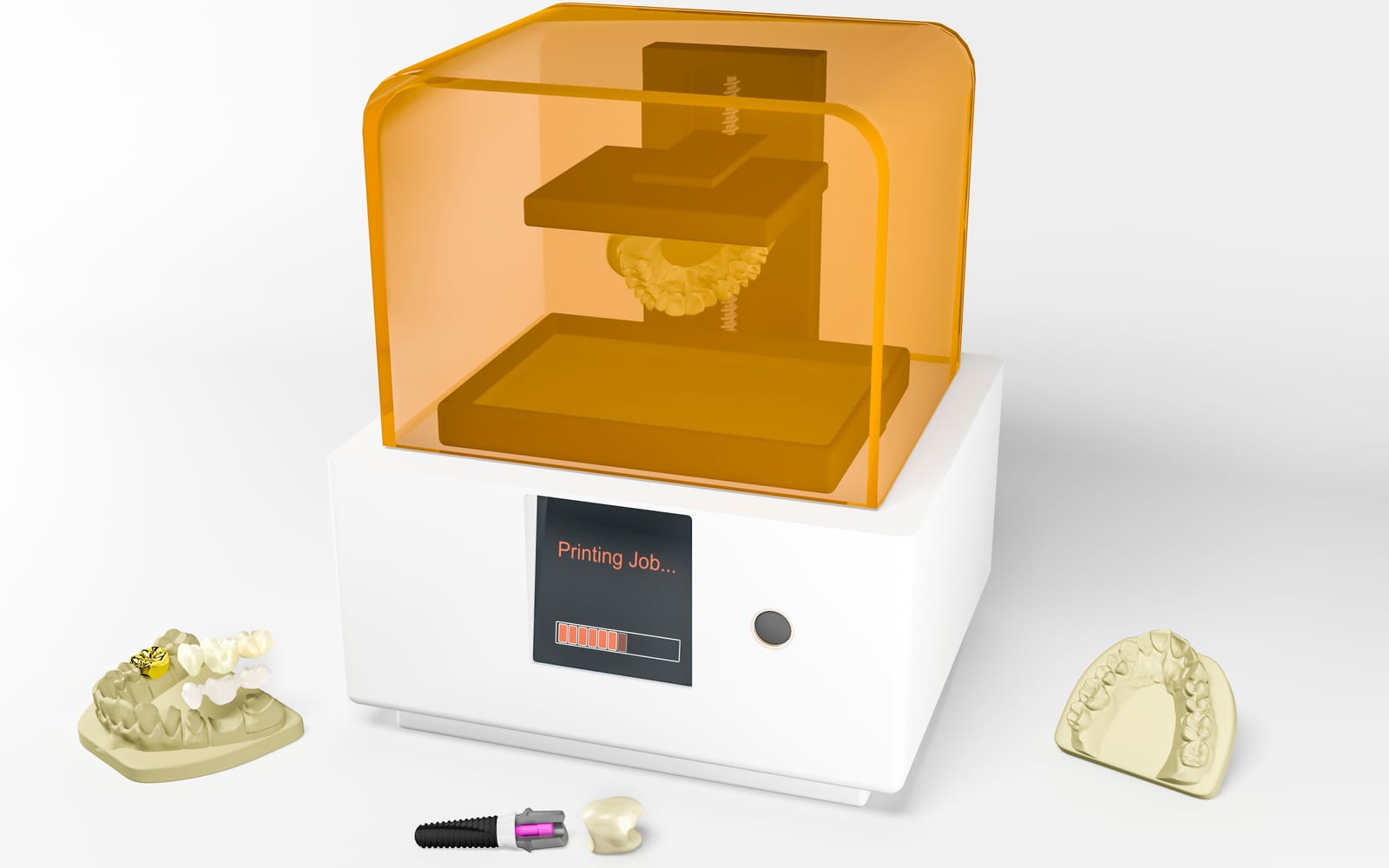

3D printing has unlimited applications with promising outlooks for medical and dental fields. While relevantly new technology, 3D printing has found its way into periodontics, a specialty of dentistry that focuses on the structure of the gums, soft tissues, and their relation with the teeth and jawbone. Its potential to become a $3.1 billion industry has high capabilities to print plastics, metals, and ceramics, making dentistry all the smoother. But how does 3D printing apply to periodontics? Let’s take a look.

Ways 3D Printing is Used In Periodontics

In a clinical setting, the periodontium is a complex tissue system of bone, gingiva, and cementum. Each tissue present different properties, with cell regeneration and signaling mechanisms controlled by separate interactions. Using 3D printing to correct damage to the periodontal tissues through multiple avenues, including:

- Guided Tissue Regeneration: Using a 3D printed membrane structure, dentists can gradually align damaged tissues and prevent the ingrowth of regenerating tissues. This allows for the bone tissue to regenerate and improve the integrity of the oral cavity for implants.

- Bone Scaffolding: 3D scaffolds can guide periodontal cells during the healing process and improve the periodontal ligaments’ organization.

- Hydrogels: In advanced cases, periodontal stem cells can have the potential to create stable targets for periodontal regeneration and improve the optimization of biomaterials during treatment.

- Root canals: 3D imaging allows periodontists to see the tooth root in all directions, allowing dentists to form 3D printed root canal guides to assist in accessing the root canal and assess pulp damage affected by gum disease and periodontal disease.

How 3D Printing Works with Patients

Surgical guides for gingival aesthetic surgery have shown positive results for patients needing improvements in the mouth’s anterior regions. Because of the accuracy, precision, and durability of these devices, periodontists have been able to use customization 3D prints of devices to aid in tissue regeneration and surgery preparation. This customization creates numerous opportunities for growth in periodontics and can give dental surgeons a better understanding of how the bones, teeth, and gums form and heal. For patients, 3D printing can provide:

- A faster, more accurate service – Originally, periodontists and other dentists had to use manual models to design treatment devices. Accuracy heavily increases because the dentist can then work with the patient to design a treatment plan that improves their gums and teeth over time and prepares them for more extensive surgeries.

- Patients save money – Before using 3D dentistry, traditional models for creating devices would be added to the patient’s bill and costs upwards of $2,000 or more. With 3D printing, patients can have easier time-saving money while gaining the services they need.

- 3D printing prospers – For those wondering about its prospects, 3D printing is an ever-growing field, improving dental work quality for both the dentist and patient. Research continues to be funded at fast paces and can help dentists deliver quality care.

For more information about 3D dentistry and how it applies to periodontics, schedule an appointment with Dr. Jean Li at Perio & Implant at Washington Metro in Rockville, MD, for more information.